In his famous 1959 lecture “There’s Plenty of Room at the Bottom,” physicist Richard Feynman explored the vast, untapped potential of manipulating matter at the nanoscale. Fast forward to today, and researchers are turning their gaze upward — not downward — to explore a new frontier in electronics.

Continue reading “There’s Plenty of Room at the Top!”Exploring Quantum Geometry with Terahertz Light: A Breakthrough in Twisted Bilayer Graphene

A recent groundbreaking study led by ICFO researchers, in collaboration with several international research groups including memebrs of the Aachen Graphene & 2D Materials Center, has uncovered previously unseen behaviors in magic-angle twisted bilayer graphene using terahertz light. As part of this international effort, the research sheds new light on the quantum geometry of this enigmatic material, revealing how the electronic wavefunctions of electrons are shaped by their environment.

Continue reading “Exploring Quantum Geometry with Terahertz Light: A Breakthrough in Twisted Bilayer Graphene”A succesful event!

The two-day workshop on Novel (2D) Materials and their Applications has been a very succesful event, with 120 participants in presence and plenty of opportunities of discussion and networking. A big thank-you to all participants an, in particular, to all speakers who contributed absolutely excellent talks.

Continue reading “A succesful event!”Forming-free, volatile resistive switching in multilayer MoS₂

Sofia Cruces and co-workers at the Chair of Electronic Devices have recently published an article in Small Science, reporting on forming-free, volatile resistive switching in multilayer MoS₂ grown by metal-organic chemical vapor deposition (MOCVD).

Continue reading “Forming-free, volatile resistive switching in multilayer MoS₂”Workshop announcement: Two exciting days dedicated to “Novel (2D) Materials and their Applications”

The Aachen Graphene & 2D Materials Center is co-organizing an exciting 2-day workshop dedicated to Novel (2D) Materials and their Applications on February 17-18, 2025.

Continue reading “Workshop announcement: Two exciting days dedicated to “Novel (2D) Materials and their Applications””Prof. Maria Fyta has joined the Aachen Graphene and 2D Materials Center

We are thrilled to announce that Prof. Maria Fyta has joined the Aachen Graphene and 2D Materials Center, significantly enhancing the Center’s research profile in computational modeling and the application of 2D materials in biotechnology.

Continue reading “Prof. Maria Fyta has joined the Aachen Graphene and 2D Materials Center”Researching MoS2-based MOSFETS – together with Ukraine

The Chair for Electronic Devices (ELD) at RWTH Aachen University is going to embark on a joint research project with the group of Prof. Alexei N. Nazarov at the Lashkaryov Institute of Semiconductor Physics (ISP) in Kyiv.

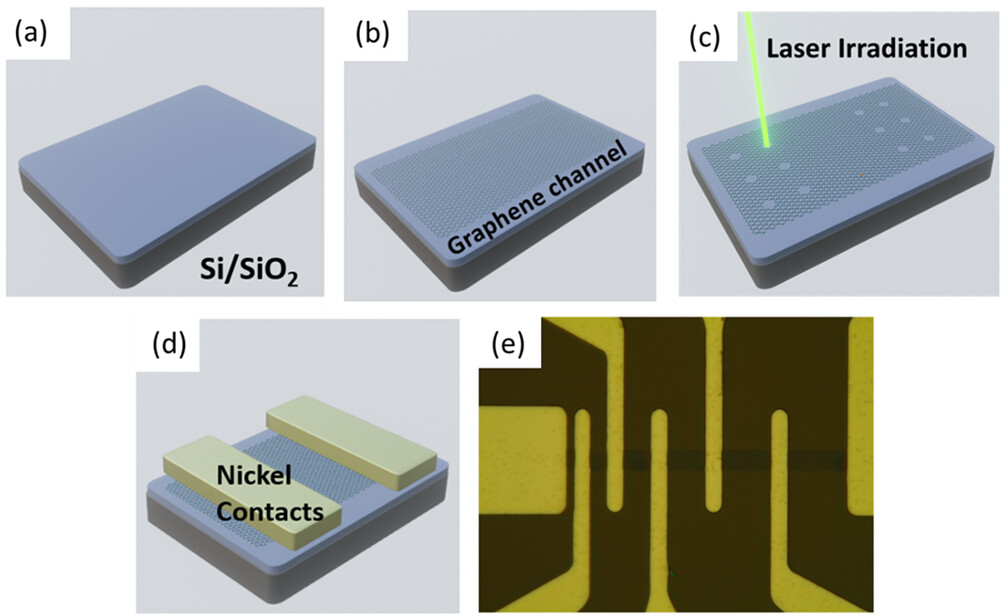

Continue reading “Researching MoS2-based MOSFETS – together with Ukraine”A scalable method to reduce the contact resistance of graphene

The exceptional electronic properties of graphene make it a material with large potential for low-power, high-frequency electronics. However, the performance of a graphene-based device depends not only on the properties of the graphene itself, but also on the quality of its metal contacts. The lack of effective and manufacturable approaches to establish good ohmic contacts to a graphene sheet is one of the factors that limit today the full application potential of graphene technology.

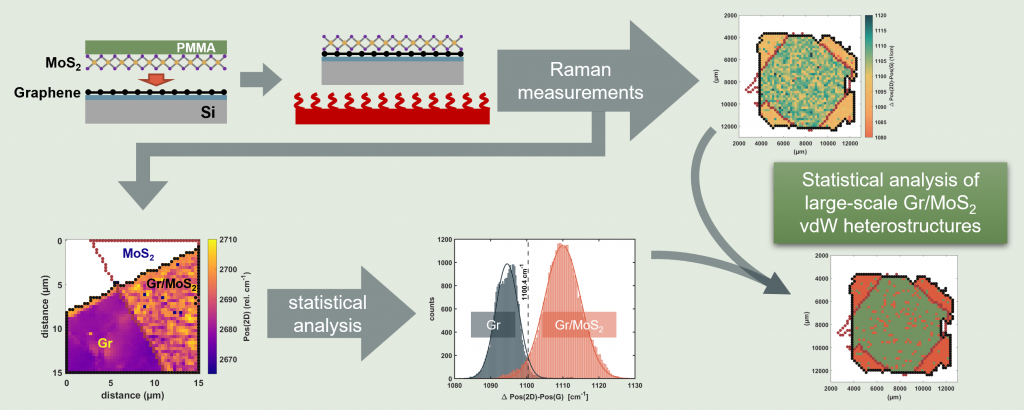

A non-destructive way to probe inter-layer coupling on millimeter-scale graphene-MoS2 heterostructures

One of the great assets of two-dimensional (2D) materials is the possibility of placing different materials on top of each other to form heterostructures with properties tailored to specific application scenarios. However, the quality of the final material stack strongly depends on the electronic coupling between the different materials. Measuring this coupling in a non-destructive way is therefore an important aspect for material development. Researchers from AMO GmbH, RWTH Aachen University and AIXTRON SE have now established a methodology based on Raman spectroscopy for estimating quantitatively the coupling between graphene and molybdenum disulfide (MoS2) in heterostructures up to the mm2-scale.

First demonstration of a CMOS inverter based on transition metal dichalcogenides on a flexible substrate

Researchers of the Aachen Graphene and 2D Materials Center have demonstrated the first CMOS inverter based on transition metal dichalcogenides (TMDC) on a flexible substrate, using two distinct TMDC materials, MoS2 and WSe2.

Continue reading “First demonstration of a CMOS inverter based on transition metal dichalcogenides on a flexible substrate”