Researchers at the Aachen Graphene & 2D Materials Center have released an open-source platform to automatically identify and classify exfoliated flakes of two-dimensional (2D) materials on a substrate, shortening one of the most time-consuming and tedious tasks in the study of 2D materials.

In their 2013 perspective article on van der Waals heterostructures, Geim and Gregorieva introduced the effective analogy of 2D materials as atomic-sized Lego blocks. The analogy illustrates well not only the sheer variety of structures that can be realized by stacking different 2D materials, but also a common bottleneck in the fabrication process: finding the right piece. As any avid Lego builder knows, finding a piece of the right size and shape can take time and patience. The same is true in the 2D materials community, where researchers often spend hours at the microscope, manually scanning exfoliated 2D-material flakes to find a crystal with the desired properties. The team of Prof. Christoph Stampfer at RWTH Aachen University has now developed an efficient tool to automatically detect and classify 2D material flakes and has made the source code openly available.

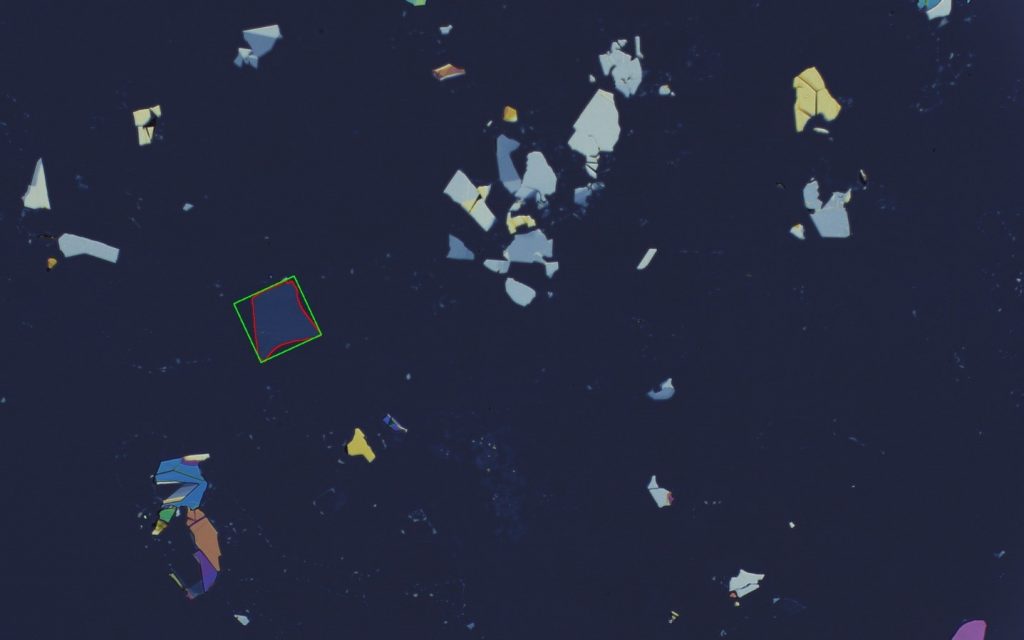

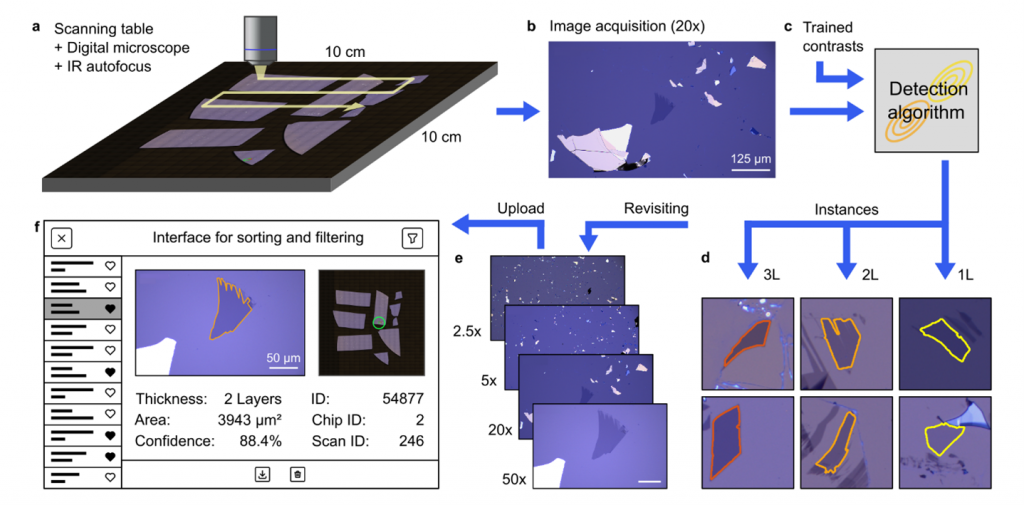

“Our goal was to develop a truly competitive alternative to the manual search by a patient and well-trained researcher,” says Jan-Lucas Uslu, who has been the main driving force behind the project. The fully automated workflow developed by Uslu and his colleagues starts at the very end of the exfoliation process, when the flakes are deposited on a silicon oxide substrate. Using classical machine learning models and a microscope with motorized scanning stage and motorized objective revolver, the system is able to reliably detect and classify all the flakes present on a substrate, indicating the number of layers of each flake, as well as its shape and dimensions. All of this information is then conveniently stored in an interactive database, along with images of the flakes taken at various resolutions. A Demo of the interactive database can be accessed here.

The automated flake search system has been tested in Stampfer’s lab for more than two years. “The effort to develop such a tool has already paid off,” says Stampfer. “Not only have we become much more efficient in assembling heterostructures, but there are also studies that we probably would have never started without a fast and efficient way to find flakes of the desired thickness.” One example is the systematic study of the dielectric screening in WS2-graphene heterostructures as a function of the thickness of the spacer layer, which was varied from one to 16 atomic layers of hBN – a daunting task without the flake-search tool.

The implementation of the automated flake search tool and the associated workflow have now been reported in the IOP journal Machine Learning: Science and Technology, while the source code has been made publicly available via GitHub in a package that includes both the control software and the detection algorithm and training routines, which can also be used as stand-alone software to identify flakes on manually captured images.

In addition to the speed and reliability, one of the attractive features of the detection algorithm is that it can be trained on just a few images, allowing new materials to be quickly integrated into the workflow. “Since the detection is based on the color contrast of the materials, which is a physical property, the training could in principle be replaced by simulations.” says Uslu.

Bibliographic Information:

An open-source robust machine learning platform for real-time detection and classification of 2D material flakes

J.-L. Uslu, T. Ouaj, D. Tebbe, A. Nekrasov, J.H. Bertram, M. Schütte, K. Watanabe, T. Taniguchi, B. Beschoten, L. Waldecker, and C. Stampfer, Mach. Learn.: Sci. Technol. accepted (2024) (or: arXiv: 2306.14845)